- P.O.Box: 17229, Ras Al Khaimah, UAE

- admin@mutanabbi.org

PROJECTS

- Home

- Project

Client:

Basrah Gas Company

Location:

Bin Umr

EPC Contractor:

AKT Oil Services Company

Services:

Balance of Plant Engineering | Year: 2016

Client:

AlFuttaim

Location:

City Center -Dubai

EPC Contractor:

ANCG LLC Year | 2017

Services:

Detailed Engineering Car Park Expansion

Client:

Basrah Gas Company

Location:

Janubia / Markazia

EPC Contractor:

AKT Oil Services Company

Services:

Replacement of Stream 291, 18” Janubia to Markazia Pipeline | Year: 2017-2018

Throughout the 17 years, TENG provided engineering services to 12 Primary Distribution Terminals and 1 Pipeline. TENG and Imperial Oil have completed hundreds of projects to improve safety, profitability and reliability at these facilities. From small maintenance projects to major revamps, our Team has executed projects in all major areas in Terminals, from pipeline receipt manifolds to loading racks.

Starting in June 2013, TENG is the Alliance Contractor for Canada Fuels Operations (Pipelines and Distribution) and Engineering Services Canada. This Contract covers 23 Primary Distribution Terminals, 24 Secondary Distribution Terminals and 6 Pipelines. The scope includes front end development; detailed engineering; procurement support; field construction support; and commissioning and startup.

TENG has an alliance contract to provide engineering services to the Nanticoke Refinery. This contract will expire in 2025. The scope of our services includes engineering (development and execution) for the projects, turnaround and maintenance groups.

Throughout the 11 years, TENG provided engineering services to all of PetroCanada’s 5 Primary Distribution Terminals in Ontario. Many projects were completed enhancing the safety and reliability of the facilities. The projects completed ranged from small maintenance type projects to major revamps.

With the merger of Petro-Canada and Suncor Energy, TENG then worked with Suncor to provide engineering services to continue with the upgrades of Suncor Energy’s Distribution Terminals. Additional facilities were added to our scope of work. In 2011 and 2012, TENG completed many EPCM projects for Suncor for its Quebec Distribution Terminals. Continuing with our long-term partnership with Suncor Energy, TENG has completed many small and major revamp projects. As well, TENG continues to manage the Distribution tank integrity management program.

Throughout the 19 years, TENG has worked with Shell Canada to complete many upgrades to the facilities to improve safety, profitability and reliability. TENG has executed projects in all major areas in Terminals. From 2010, TENG has managed the storage tank integrity program for all Distribution Terminals in Canada. One of our Engineers has been seconded to be the Tank Program Oversight for all of Canada. In addition our Engineers provide the front end work, scope writing and project management for tank projects in Ontario, Manitoba and Alberta.

TENG was mandated to develop a tank integrity management program. Its objectives were to:

- Increase the operability and reliability of this class of assets

- Standardize the methodology and approach to tank repairs and upgrades

- Increase the predictability and reliability of the outcomes of tank repairs

and upgrades - Manage cost

The program has matured over the years where there are:

- A database compiled for all API 650 storage tanks

- Benchmarking for cost and duration of work

- Lean initiatives to improve on our performance

TENG has five Mechanical Engineers who are API 653 qualified Inspectors

Client:

Ruetgers Canada Inc.

Location:

Hamilton, Ontario

Project & Year:

European Pitch TK-92 | 2012

Value of Project:

$5 million Cdn

TENG was contracted with the frontend design, detailed engineering, procurement assistance and construction coordination for the storage and blending of various pitch products. This required a series of blending pumps and heat exchangers to maintain an operating temperature of approximately 200 oC.

A vapour balancing system was also required to ensure that vapours were not released to the atmosphere.

The scope involved designing a 17m (56′) diameter by 21.3m (70′) high API 650 Appendix M storage tank, with a design temperature of 260 oC. One of the major challenger was to design a tank foundation located on reclaimed land.

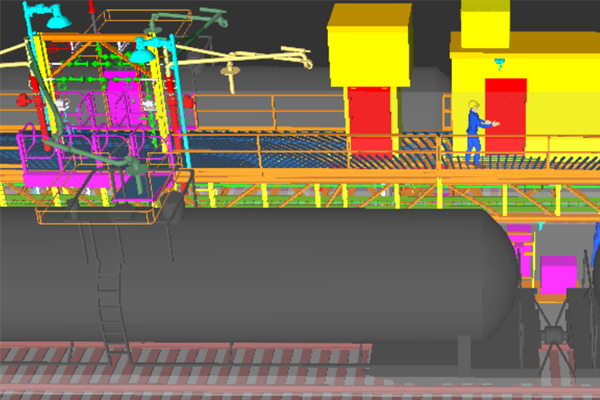

TENG worked with the Imperial Oil Nanticoke Refinery to develop the front end engineering for rail loading of asphalt. The execution plan required the design to be modular in concept. Sections of the platform and all equipment would be fabricated and assembled in a shop and delivered to the site for installation.

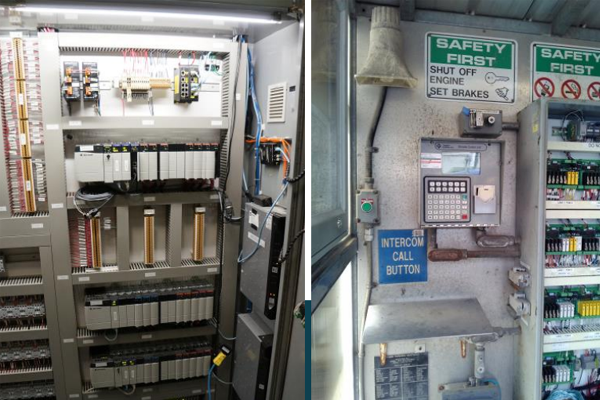

TENG and Suncor have worked diligently to create and implement standardized automation packages for all of Suncor’s Distribution facilities.

TENG was responsible for preparing the Design Specifications and developing the System Architecture. As part of the front end engineering, TENG evaluated and made recommendations on the hardware and software selection. Vulnerability assessments (risk analysis) were conducted to ensure due diligence and to minimize any risks to the projects.

TENG designed, simulated, tested and implemented the:

- network – Ethernet, industrial protocols, bridges, firewalls, gateways, VPNs

- hardware – PAC, PLC, remote I/Os, industrial computers, control stations

- software – SCADA development, HMIs, web servers, OPC, protocol

drivers, databases, email servers, integration into ERP/TMS, patch management - PLC programming

Shell Canada contracted TENG to prepare the front-end engineering and execute the projects as EPCM projects.

The mandate was to replace and upgrade the obsolete PLCs, HMIs and network equipment for several Distribution Terminals across Canada.

This is a multi-year, multi-facility, multi-phase project where the first phase was to replace all obsolete, non-supportable PLCs, software and HMIs.

The project involved defining and standardizing on a new system architecture but still incorporating site specifics as the project involved rolling out this project over numerous sites across Canada. It involved numerous stakeholder consultations and scope of work definitions. It involved delivering a pilot HMI so that Operations could train and provide feedback prior to execution and commissioning.

Subsequent phases include addressing process safety and safety critical systems whereby SIL rated systems and PLCs are engineered and installed and commissioned.

Our Engineers have TUV and SIS training for this work.

The scope of the project was to provide the facility the means to prepare a new over-the-counter pharmaceutical product.

This involved developing the facility to be able to receive and store raw materials (liquids and emulsions) in bulk, while still maintaining pharmaceutical good manufacturing practices. Some of the raw materials were classified as flammable while others were not; and one was classified as toxic.

As well the existing facility was modified to reuse the existing assets (pressure vessels) and complement with new pressure vessels and piping to allow for the formulation of the new OTC product. The sub-systems designed included a vacuum system, a pigging system, a wash-in-place system; and an automated manufacturing system.

Can we help you?